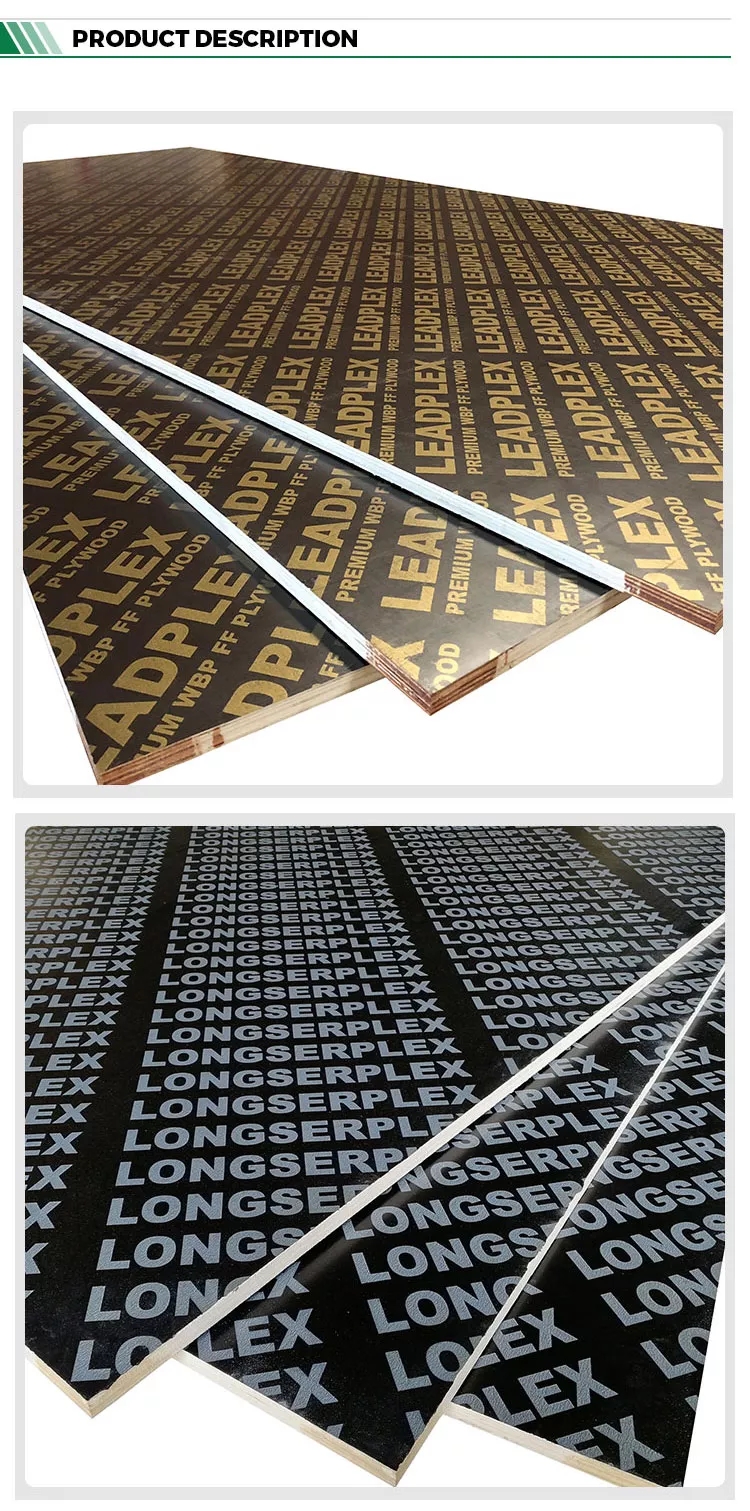

Main production: construction template, film-covered board, small red board, big red board, construction wood square, etc. The laminated board has the characteristics of flat and smooth surface, uniform thickness, good waterproof performance, and easy demoulding. After 120 minutes of cooking in Buddha water, it can still meet the bonding strength requirements. The turnover number is more than 15 times. It is the preferred template for the Luban project.

Laminated board specifications: common specifications size: 1830*915*(11-20)mm 1220*2440*(12-20)mm

Process characteristics of laminated board:

1. Choose 5-7 years old eucalyptus logs, which have small stutter and good toughness, and select full-core veneers in the peeling;

2. Adopt high-quality pine and eucalyptus whole-core first-level core boards to assemble billet boards with distinct layers and smooth surface. There is no cavity in the sawing, and the density is 700kg/m3.

3. The surface coating is phenolic resin with strong waterproof performance, and the core board is made of tri-amino glue (single-layer glue up to 0.3KG), and layer-by-layer glue is used to fully bond and increase the bonding strength by 5-10%.

4. The hot pressing pressure is 120% of the theoretical pressure, and it is forbidden to reduce the pressure in order to preserve the thickness.

5. After the template is polished, it is coated (secondary molding) to ensure that the template is flat and smooth, easy to demold, reduce plastering operations, and improve work efficiency.

Product use: construction templates for bridges, high-rise buildings, tunnels, railways, etc.

Processing cycle: Common specifications of building templates are usually placed 3 days in advance, and urgent orders need to be notified 1-2 days in advance. Generally, factories will stock 10,000 to 10,000 of templates of conventional specifications to meet the urgent needs of customers.

|