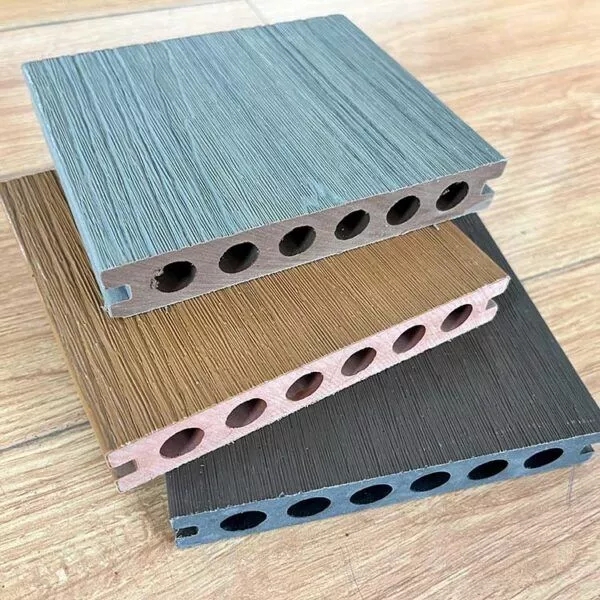

Co-extruded wood plastic decking refers to a type of flooring produced by extrusion technology, which is evenly and firmly covered with a co-extruded layer, and which has the advantages of traditional plastic wood decking, but also has stronger resistance to wear, scuffing, corrosion and weather.

Performance of co-extruded plastic wood flooring.

(1) Waterproof, moisture-proof. Solve the problem of wood products to wet and watery environment after absorbing water and moisture, easy to rot, swelling and deformation

(2) Insect and termite resistant, effectively eliminating insect harassment and extending service life

(3) Colourful, with a wide range of colours to choose from. It has a natural wood texture and wood grain, but can also be customized.

(4) Strong plasticity, can fully reflect the individual style.

(5) Highly environmentally friendly and recyclable. European environmental standards, recyclable, saving the amount of wood used.

(6) High fire resistance. It can be effectively flame retardant, with a fire rating of B1, self-extinguishing in case of fire, and does not produce any toxic gas.

(7) Good processability, can be ordered, can be planed, can be sawed, can be drilled, and the surface can be painted.

(8) Simple installation, convenient construction, saving installation time and costs.

(9) No cracking, no expansion, no deformation, no need for repair and maintenance, saving maintenance and repair costs.

(10) Good sound absorption, good energy saving, energy saving up to 30% or more.

wpc decking co-extruded protective layer.

The protective layer of co-extruded plastic wood decking is uniquely formulated to create a clear wood grain and natural colour, while wrapping on all sides to protect the board in all directions, making it more wear resistant, scratch resistant and stain resistant. In high-traffic areas, it protects against scratches caused by foot traffic and hard objects and stands up to the rigours of nature. The protective layer is produced at the same time as the panels and will not separate.

Co-extruded plastic wood flooring application scope.

Design and production of plastic wood park leisure seats, rubbish bins, flower boxes, signage, guardrails, gazebos, fences, porches, walkways, platforms, landscaping sketches, waterfront walkways, piers, park walkways, swimming pools, leisure squares, balconies, wooden houses, gazebos.

Product life span: 25 years of product quality.

The abrasion and scratch resistance of co-extruded WPC decking is more than five times greater than that of the first generation of plastic wood, effectively preventing breakage caused by abrasion and scratching of hard objects, making it particularly suitable for high traffic situations.

In addition, the product’s strong outer layer is resistant to the penetration of coloured and oily liquids, making the surface very easy to clean and long-lasting. This layer also increases the resistance of the flooring to sunlight, rain, snow, acid rain and seawater, giving it a very long life.

The colours and textures of co-extruded plastic wood flooring are more realistic and long-lasting, with rich variations and shades.

|